- Dock Equipment

- Edge of Dock Leveler

- Hydraulic Edge of Dock Leveler

- Mechanical Pit Leveler, A Series

- Mechanical Pit Leveler, M / MX Series

- Hydraulic Pit Leveler

- Hydraulic Vertical Lift

- Air Powered ‘Air Bag’ Dock Leveler

- LoadMaster™ Hydraulic Dock Leveler

- DockMaster Lift / Leveler

- Automatic Trailer Restraint

- Mechanical Trailer Restraint

- Dock Seals

- Dock Shelters

- Lifts

- Doors & Gates

- Board & Plates

- Allied Equipment

- Literature

- Blog

- Quote

Jan

Months and years of repeated impact between trucks or trailers and docks can result in costly repairs. Loading dock bumpers serve as a solution to this issue by protecting both components from damage.

These—typically rubber and sometimes steel covered—devices serve two primary functions: impact absorption and friction reduction. They can absorb as much as 80% of the impact when the truck or trailer is backed directly into the dock (a common occurrence in high-traffic areas). Additionally, they help alleviate any friction caused when truck leveling devices elevate the vehicle to dock height.

When installed at loading docks, loading dock bumpers serve as a cushion between trucks or trailers and docks. This quality allows the former to collide with the latter without causing or incurring dents or abrasions. When used in other areas of warehouses and factories, they prevent damage to and from forklifts and other industrial equipment.

As these devices serve a critical function, we’ve put together the following blog post to help industry professionals understand the various types of loading dock bumpers available and how to choose one for their unique application.

Types of Loading Dock Bumpers

Standard dock bumpers are available in a variety of heights and can be mounted horizontally or vertically to accommodate different types of loading docks. In addition to the two positioning configurations, there are three main types of dock bumpers employed:

- Molded. Molded dock bumpers are suitable for low to medium traffic areas, such as loading docks or locations where forklifts and material handling equipment are used. They consist of a single, heavy-duty molded piece, allowing for a more aesthetic installation. Compared to other bumper types—i.e., laminated and steel face—these bumpers are more prone to damage such as chipping and gouging.

- Laminated. Laminated bumpers are designed to anchor to virtually any surface to provide protection, including on loading docks, truck levelers and wells, and walls. These devices feature durable, laminated rubber construction that provides them with greater wear resistance than molded dock bumpers. They are also available in a wide range of thicknesses, lengths, and heights.

- Steel Face. Steel-plated bumpers incorporate a protective, high-carbon steel face that provides additional impact absorption. These bumpers demonstrate the greatest durability for high-traffic areas where trucks and trailers are repeatedly repositioned, raised, and lowered for loading and unloading operations.

Selection Considerations for Loading Dock Bumpers

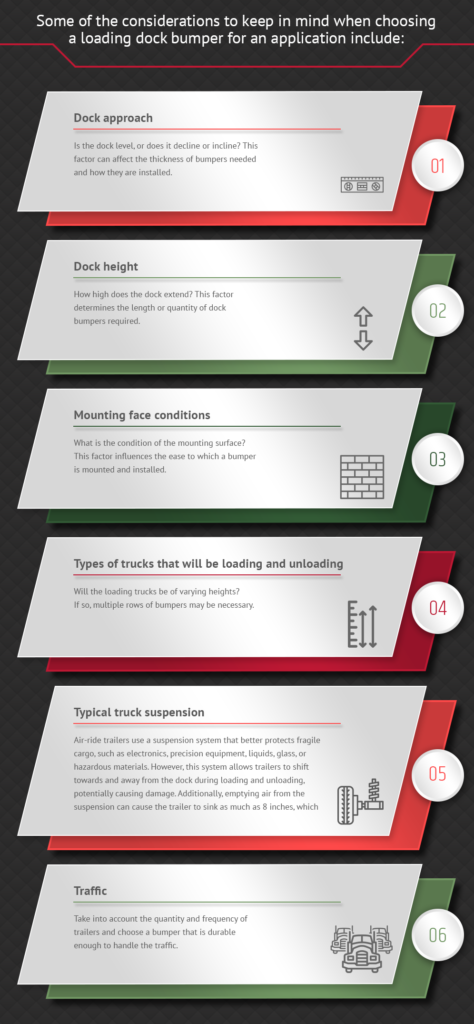

Some of the considerations to keep in mind when choosing a loading dock bumper for an application include:

- Dock approach. Is the dock level, or does it decline or incline? This factor can affect the thickness of bumpers needed and how they are installed.

- Dock height. How high does the dock extend? This factor determines the length or quantity of dock bumpers required.

- Mounting face conditions. What is the condition of the mounting surface? This factor influences the ease to which a bumper is mounted and installed.

- Types of trucks that will be loading and unloading. Will the loading trucks be of varying heights? If so, multiple rows of bumpers may be necessary.

- Typical truck suspension. Air-ride trailers use a suspension system that better protects fragile cargo, such as electronics, precision equipment, liquids, glass, or hazardous materials. However, this system allows trailers to shift towards and away from the dock during loading and unloading, potentially causing damage. Additionally, emptying air from the suspension can cause the trailer to sink as much as 8 inches, which can push against bumpers anchored to the dock.

- Traffic. Take into account the quantity and frequency of trailers and choose a bumper that is durable enough to handle the traffic.

Protect Important Dock Areas and Equipment With Aaron Bradley

Installing loading dock bumpers prevents damage to dock structures and freight vehicles, minimizing the need for costly repairs or replacements. With the variety of dock bumper styles available and options for horizontal and vertical configurations, choosing the right dock bumpers for your application is easier than ever.

At Aaron Bradley, we provide dock bumpers in a variety of sizes to suit virtually every industrial application. Our bumper offerings can withstand up to 1500 lbs. of pressure and include:

- Laminated bumpers with end angles for flexible installation or flat “weldable” plates

- Extra-long and extra-thick bumpers

- Molded and fabric-reinforced rubber bumpers

- Extruded rubber bumpers

To learn more about the dock bumper offerings at Aaron Bradley, visit our Loading Dock Bumpers page or request a free quote today.